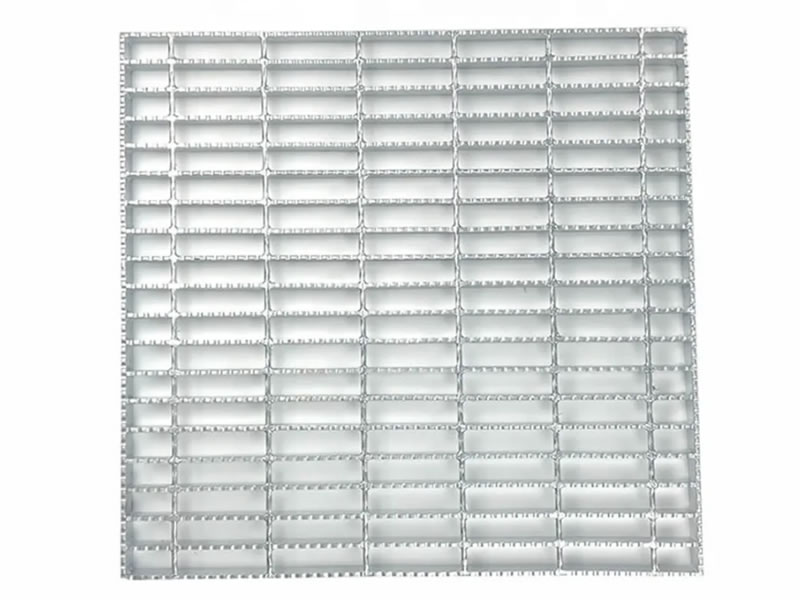

Serrated Welded Grating-Serrated Open End Steel Grating

Serrated opening bar grating offers a non-slip texture, ideal for flooring and walkways in factories or industrial workshops requiring safe treading. This grating permits light and air circulation while providing efficient drainage. While it's predominantly made from either galvanized or non-galvanized carbon steel, common sizes include 900 x 1400 mm, 900 x 900 mm, 900 x 1200 mm, 1000 x 650 mm, and 1100 x 700 mm. Depending on the application, this grating can be secured using four methods: welding, swage-locking, press-locking, or riveting.

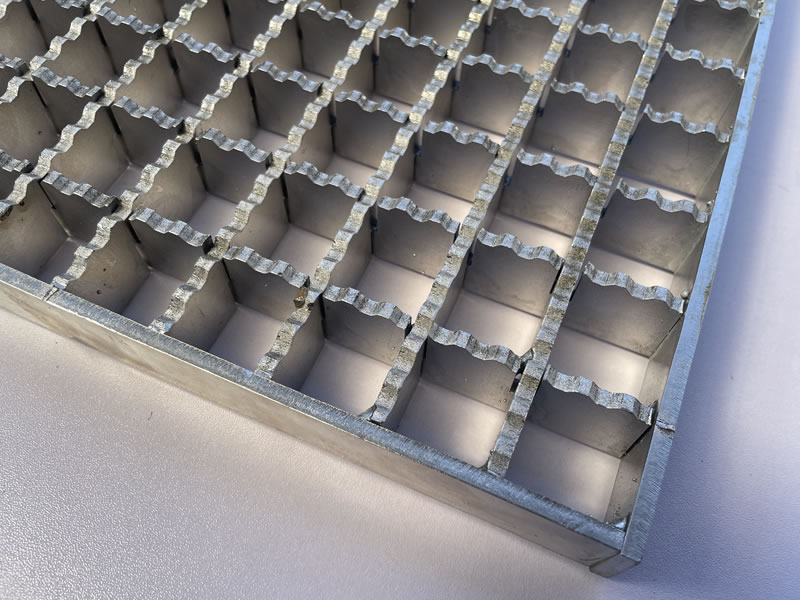

Serrated welded grating, also known as zigzag welded grating, features bearing bars with a serrated surface welded to crossbars. This design offers enhanced slip resistance compared to smooth grating and is commonly used for platforms, walkways, and drainage covers.

The main characteristics of serrated welded grating are:

Benefits

- Typically found in industrial and commercial spaces like walkways, platforms, and drainage covers, its key benefits include:

- Slip Resistance: Its serrated design ensures safety in areas prone to slipping, such as industrial floors and stair treads.

- Load Bearing: Serrations increase contact surface area, enhancing load distribution and capacity.

- Durability: Its welded construction ensures it can handle heavy loads and frequent traffic.

- Drainage & Ventilation: Spaces between bars allow efficient liquid drainage and promote airflow, minimizing corrosion or mold risks.

- Versatility: Available in materials like carbon steel and aluminum, it can be tailored to specific size or capacity needs.

Serrated Surface: Unlike the smooth surface of traditional bar gratings, the bearing bars in serrated welded grating have a notched surface. These serrations provide slip-resistance, which can be crucial in environments where the grating might get wet or oily.

Welded Connections: The bearing bars (the main load-bearing elements) and the cross bars are welded together at their intersection points. This welding provides a strong, durable connection and ensures that the grating maintains its shape and structural integrity over time.

Material: Most commonly, serrated welded grating is made of carbon steel, but it can also be made from stainless steel or aluminum depending on the application's requirements.

Finishes: To improve resistance to corrosion, serrated welded gratings can be galvanized (coated with a layer of zinc). They can also be painted or given other finishes to enhance aesthetics or to provide further protection against environmental factors.

Applications: Serrated welded gratings are often used in industrial settings where slip resistance is a priority. Examples include walkways in factories or oil rigs, platforms in wastewater treatment plants, and stair treads.

Customized product specifications

Serrated Open End Steel Grating

Serrated Open End Grating Hot Dip Galvanized Finish, Cross Bar Twisted

Size:995mm x 6000mm

Bearing Load Bar Size: 25mm x5mm Serrated

Bearing Bar Pitch:30mm

Cross Bar Size:6mm Twisted

Cross Bar Pitch: 100mm

Width: Open End

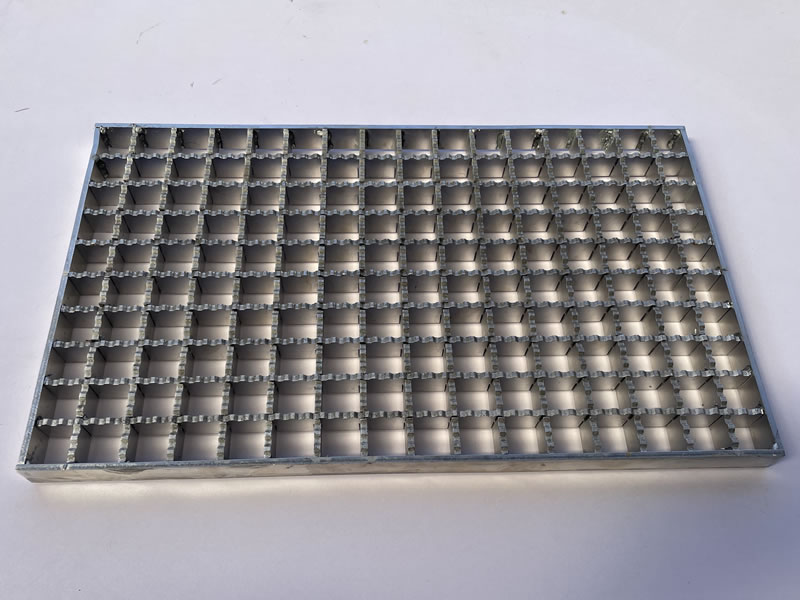

Hot Dip Galvanized Steel Grating with serrated bearing bars 38X5 mm at 40 mm centres

Cross bars at 100 mm centres

Additional 7 mm diameter bars in between of load bearing bars

Grating size: 30x50 30/5

Panel size: Length x width-1000x650mm)

When specifying or ordering serrated welded grating, it's important to consider the load-bearing requirements, the size of the spaces or "openings" in the grating, the material, and the type of finish, among other details.

SWG-1 Serrated Welded Grating

SWG-2 High quality Serrated Welded Grating

SWG-3 Pressure Welded Steel Grating Serrated Flat Bar Drain Cover